I gathered the Chapter 4 components and tools from a variety of sources.

Below, I've included description, part #, price, and where purchased.

Looking online, I paid way more than I should have for the various chips, but I was able to obtain them locally and visually inspect them. I also got a 20 minute education in other chips, so I figure the extra I spent was worth the extra information... future chip purchases, however, will likely come from Mouser.com where I think I see the best prices... please feel free to chime in about what you've found in terms of prices.

Components

ACK Supply for all chips below:

555 Timer chips x10, CA555E RCA, $0.80 each

$1.59 each for

CD74HC00E RCA

CD74HC02E RCA

CD74HX04E RCA

CD74HC08E RCA

CD74HC32E RCA

CD74HX86E RCA

CD4026BE RCA, $2.59 each

7492, $2.05 each

7406, $1.67 each

74LS27, $1.59 each

-----

Radio Shack Online items below

Item: 2761995

Description: 8-Pin Retention Contact

Quantity: 5 @ $.48

Item: 2761999

Description: 14-Pin Retention Contact

Quantity: 5 @ $.99

Item: 2761998

Description: 16-Pin Retention Contact

Quantity: 5 @ $.99

-----

AllElectronics.com items below

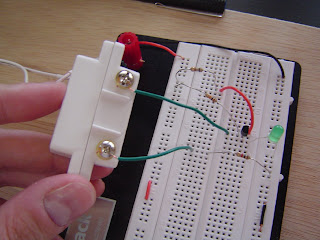

12-key numeric keypad - KP-12 (12 BUTTON KEYPAD - (KP-12)) $4.95

-----

Mouser.com components below

638-HLMPK150 Red LED, 660nm, $0.18 each

604-BC56-11EWA,HI EFF RED DIFFUSED numeric display, $2.73 each

Latching Relay 769-DS2E-SL2-DC5V 2A 5VDC DPDT, $4.86 each

10K Trimmer 652-3266Z-1-103LF 1/4" 10Kohms 10% $2.94 each

Voltage Regulator 512-LM7805CT 1A Pos Vol Reg , $0.37 each

Tactile Switches (already purchased for earlier chapter)

-----

Radio Shack Store components below

100K Potentiometer, 271-092 $2.99 each

10K Potentiometer, 271-1715 $2.99 each

5K Potentiometer (already purchased for earlier chapter)

On another note -sorry for the delay in posts. We've had a death in the family and I'll resume posting on Tuesday when I get back in town.

On another note -sorry for the delay in posts. We've had a death in the family and I'll resume posting on Tuesday when I get back in town.